The Larta series includes 13 milk coolers of different volumes, from 50 to 2500 liters, cisterns that meet the needs of any milk and cheese production plant.

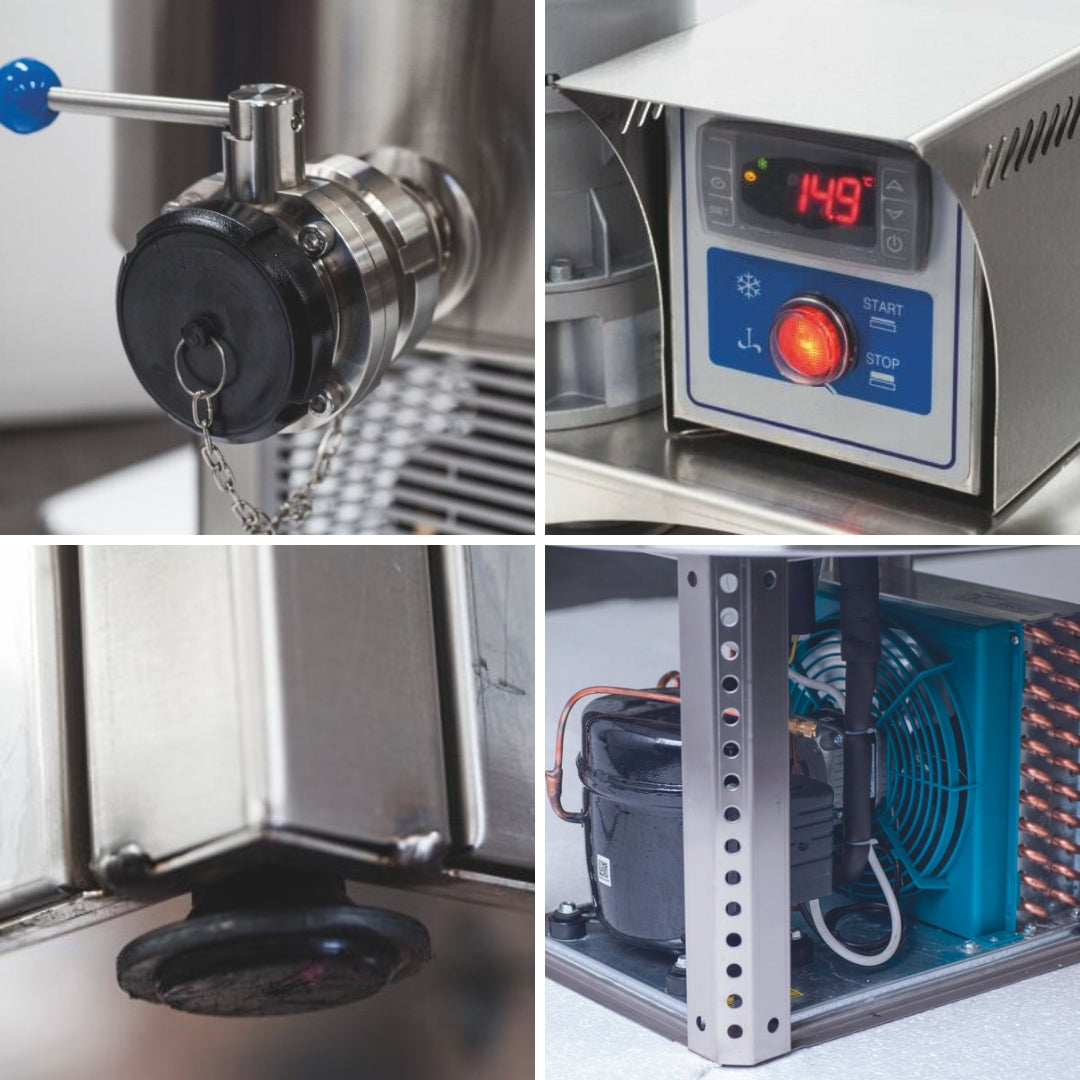

The common feature of all tanks of the Larta series is fast and permanent cooling and maximum energy saving.

All our tanks are made of materials suitable for the production of food products according to European and American standards ISO5708 / EN13732 / 3A.

Thus, the cooling time is observed to prevent the growth of bacteria and acidification of the milk (lowering of рН). The milk is mixed with a special shaft with a motor-reducer at the appropriate speed to achieve proper fat homogenization and uniform cooling throughout the milk volume without foaming.

The carefully considered design of the tanks also provides other valuable advantages for milk production, such as economy of space, ease of operation and ease of movement, assembly, repair and maintenance.

The cooling mechanisms and their capacities are designed to meet the needs of sheep and goat farms and cow farms.

| MODELS | A | A1 | A2 | B | B1 | B2 | H | h1 | h2 | h3 |

| LRT50 | 560 | 280 | 365 | 520 | 280 | 365 | 1350 | 820 | 1050 | 440 |

| LRT100 | 780 | 330 | 400 | 680 | 410 | 500 | 1660 | 980 | 1190 | 420 |

| LART200 | 1030 | 530 | 610 | 890 | 530 | 610 | 1520 | 990 | 1220 | 420 |

| LART300 | 1130 | 530 | 620 | 990 | 530 | 610 | 1700 | 1030 | 1250 | 420 |

RECEIVING THE GOODS ON SITE AT OUR WAREHOUSE

Presses can be ordered and received free of charge at the Rēzekne warehouse at the address Strādnieku kārsiela 7. To receive an order, you must have an identity document and order number with you. If your order will be received by another person, indicate him as the recipient when placing the order. And if the buyer is a legal entity, a power of attorney must be present.

DELIVERY OF GOODS BY COURIER TO THE SPECIFIED ADDRESS

If you have selected home delivery, we will deliver your order within 1-3 working days, unless a different delivery time is specified for the selected item(s). Couriers deliver orders along a pre-planned route, so it is not possible to choose an exact delivery time.

DELIVERY OF GOODS TO OMNIVA PARCEL

If you have selected delivery to an Omniva collection point or post office, they will be delivered within 1-3 working days, unless a different delivery time is specified for the selected item(s).

Important!

Delivery of the order to the Omniva parcel is possible only if the goods do not exceed the specified package dimensions (39cm x 38cm x 64cm) and weight (up to 30 kg).

Omniva pakomāts

Omniva pakomāts Venipak kurjers

Venipak kurjers